High Automation Wood Wastes Gasifier Stove

Basic Info

Model No.: DY-L2000

Product Description

Biomass gasification power generation polygeneration system is a technology that syngas is produced by pyrolysis of various low calorific value solid biomass raw materials at high temperature and then supplied to generating units for power generation. In addition to providing users with their own power, the generated energy can also be sold on the grid.

High Automation Wood Wastes Gasifier Stove

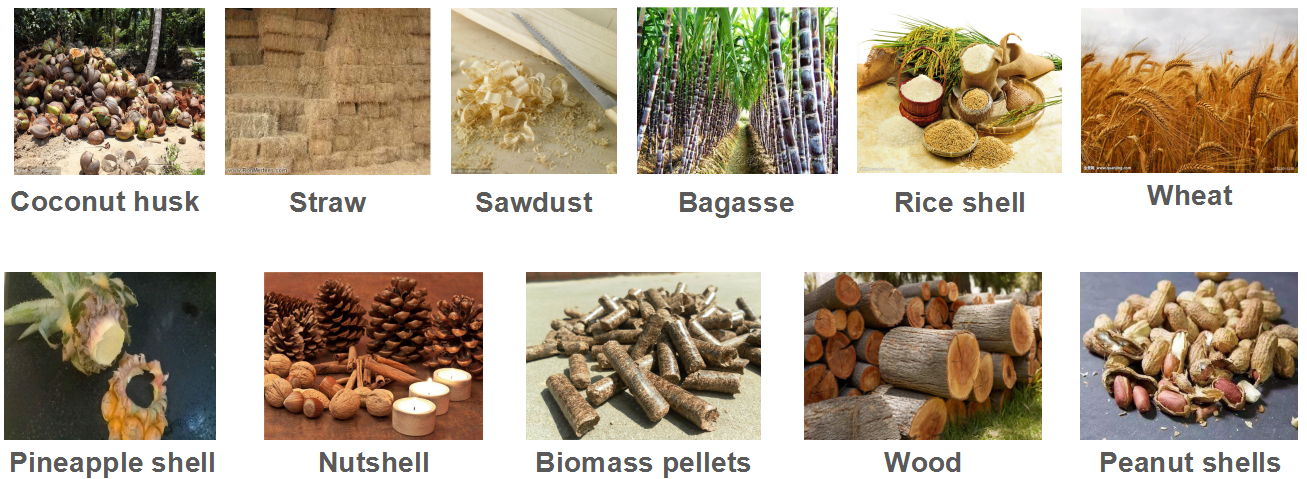

The biomass gasification power generation system developed by our company uses fluidized bed gasifier and gas purification device to convert rice husks, wood chips and straw and stalks into clean fuel gas. The installed capacity of single machine can be made according to user requirements and demands. The system is reliable in operation and easy operation. After firing for more than 20 minutes, it can provide fuel gas to engine-generator unit to generate electricity at 20th minutes after start. In addition to providing customer for self-usage, they can also sell extra power to the office power grid.

Parameters:

| Type | DY-L2000 | |

| Biomass-gas | Theoretical output (m³/h) | 2000m³ |

| Contents | CO:20-25%,H2:8-15%, CH4: 2-4% , CO2: 2-4% ,N2 :40-45% , O2:≤1.0% | |

| Fuel Material | Material ton/h | 0.75~0.95 |

| Size | Wood chips:30-50mm ; plant stalks or straw≤100mm | |

| Moisture | Better moisture ≤ 15% (Max moisture ≤20%) | |

| Heat Value of Syngas | 1100-1300Kcal/m³ | |

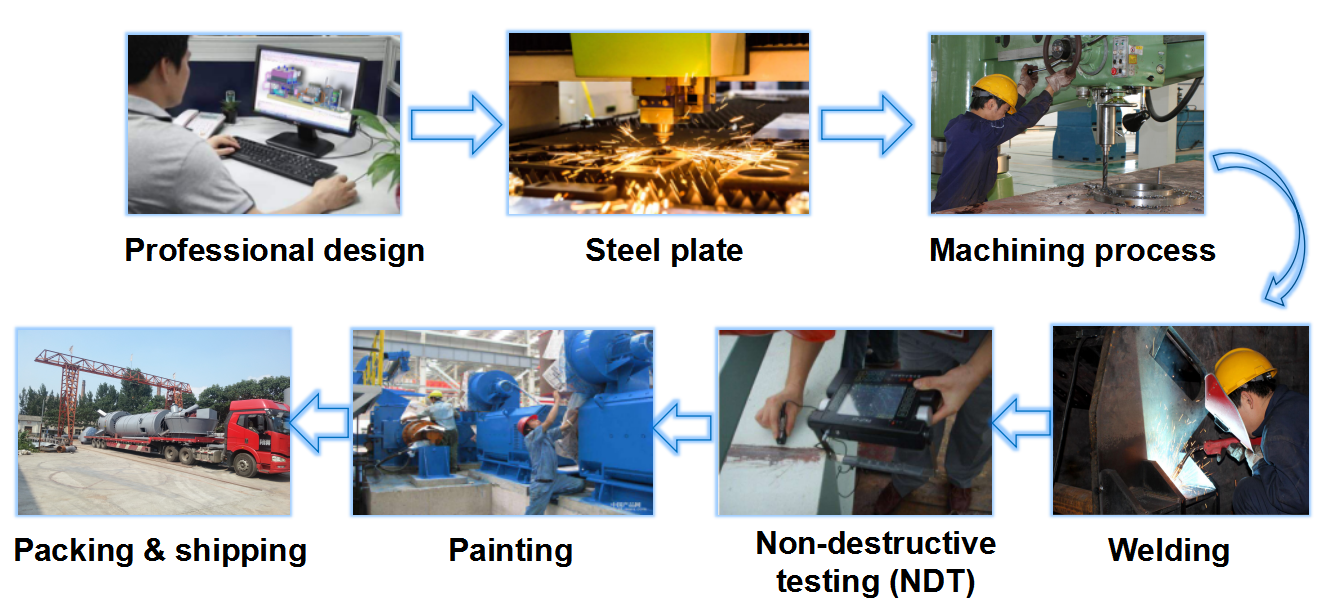

Producing Procedure:

Advantages:

1) Technical advantages: Circulating fluidized bed,advanced technology, large and stable gas production, can start power generator unit in 20 minutes.

2) The equipment is small in size, less footprint area require, flexible layout, and easy to operate and maintain.

3) The whole system and auxiliary equipment are all designed with high-grade explosion-proof design technology, which is more safe and reliable.

4) Energy-saving advantages: 60%-80% energy saving than natural gas and liquefied gas, high thermal efficiency.

5) Environmental advantages: Dust-free emission during operation, safe and environmentally friendly.

6) Return on investment: low energy consumption and significant economic benefits.

7) Wide range of usage: wide range of raw materials resources.

Our Service:

Pre-sale services:

(1) device model choice.

(2) According to customer's special requirements, design and manufacture of products.

(3) Training technical personnel for clients.

(4) The company is free of charge to the user on-site engineering and technical personnel planning site for the user to design the best processes and program.

After-sale services :

(1) free to assign a dedicated service personnel, arriving at the scene and guiding customers' installation.

(2) equipment installation.

(3) on-site training of operators.

(4) complete sets of equipment installed, 1-2 full-time technical staff to stay free of charge to help customers on-site production of 1 month, until the user' satisfaction.

Company Profile:

Product Categories : Biomass Power Plant > Wood Gasifier Power